Expanded Polystyrene (EPS) foam makes a significant contribution toward enabling modern vehicles to be lighter, more fuel efficient and safer than older models yet still be stylish enough to attract new buyers. By strategic reliance on EPS foam, the automotive industry meets these disparate design challenges in elegant and cost effective fashion.

3 Benefits of EPS Foam in Automobiles: Impact Absorption, Passenger Protection, & Fuel Economy

Tags: eps, expanded polystyrene, custom molding, eps indiana, eps michigan, eps ohio, eps kentucky, eps Pennsylvania, eps tennessee, plastic #6, eps products, passenger protection, automotive materials, impact absorption

Tags: eps, expanded polystyrene, transport packaging, industrial packaging, protective packaging, custom molding, building materials, insulated concrete forms, insulation panels, eps products

Insulation is not the most marketable building component, but it is essential to both the performance of the building and health of the occupants. Without sufficient insulation, large portions of the energy used to heat or cool a building will be lost to the outdoors. Insufficient insulation can also lead to mold problems as heated air rapidly cools and causes water vapor to condense. Historically, mud, asbestos, and cork were used as insulation materials for buildings and pipes. The insulation products available today are much more effective, especially in conjunction with air sealing and ventilation.

Tags: eps, expanded polystyrene, custom molding, building materials, insulation, insulated concrete forms, icfs, insulation panels, eps indiana, eps michigan, eps ohio, eps kentucky, eps Pennsylvania, eps tennessee, eps recyclable

ICFs are forms for poured concrete walls that stay in place as a permanent part of the wall assembly, serving as continuous insulation as well as a barrier against air and sound entry. To give the wall greater strength, steel reinforcement is placed both horizontally and vertically in the forms before the concrete is pumped or poured inside.

Tags: eps, expanded polystyrene, custom molding, building materials, insulation, insulated concrete forms, icfs, insulation panels, eps indiana, eps michigan, eps ohio, eps kentucky, eps Pennsylvania, eps tennessee, eps recyclable, plastic #6

Insulating concrete forms (ICFs) are hollow “blocks” or “panels” made of expanded polystyrene insulation (EPS) or other insulating foam used to permanently form concrete structures. ICFs result in cast-in-place concrete walls that are sandwiched between two layers of EPS foam material, providing insulation for the structure they enclose. This combination creates a wall with many desirable properties: strength, insulation, and noise control.

Tags: eps, expanded polystyrene, custom molding, building materials, insulation, insulated concrete forms, icfs, insulation panels, eps indiana, eps michigan, recyclable, eps ohio, eps kentucky, eps Pennsylvania, eps recyclable, plastic #6

EPS Cold Chain Packaging Solutions for Shipping Pharmaceutical & Life Science Products

Not all cold chains are created equal – some are longer, more rigorous and more time consuming from end to end. Land, sea and air modes all have different structures for keeping perishable products fresh throughout the transport chain. Certain supply chains may only require one transportation mode, but many times ground shipments are one link in a combination of transport modes. Cold chain concerns include:

Tags: transport packaging, custom molding, pharmaceutical packaging, cold chain solutions, cold chain containers, perishable goods, eps coolers, medical packaging, eps indiana, eps michigan, eps ohio, eps kentucky, eps Pennsylvania, eps tennessee, mail-order packaging, life science product packaging

Reduce Waste & Spoilage with Intelligent Packaging for Perishable Goods

Food waste is often considered environmentally benign because it is ‘biodegradable’ but consider this: globally, about a third of the food produced for human consumption goes to waste — which means that a third of the water, land use, energy and financial resources that went into producing it are also squandered. For perspective, over 100 billion pounds of food, or more than a quarter of the 400 billion pounds of edible food, is spoiled each year during transport. When it comes to protecting food, the right package can dramatically reduce waste and have a major positive impact on the environment.

Tags: eps, expanded polystyrene, transport packaging, protective packaging, foam packaging, custom molding, coolers, food packaging, spoilage, cold chain solutions, cold chain containers, perishable goods, meat packaging, dairy packaging, eps coolers, ice cream packaging, cheese packaging, mail-order packaging

Having Trouble Choosing an Insulation Material?

Tags: eps, expanded polystyrene, custom molding, building materials, insulation, insulated concrete forms, icfs, insulation panels

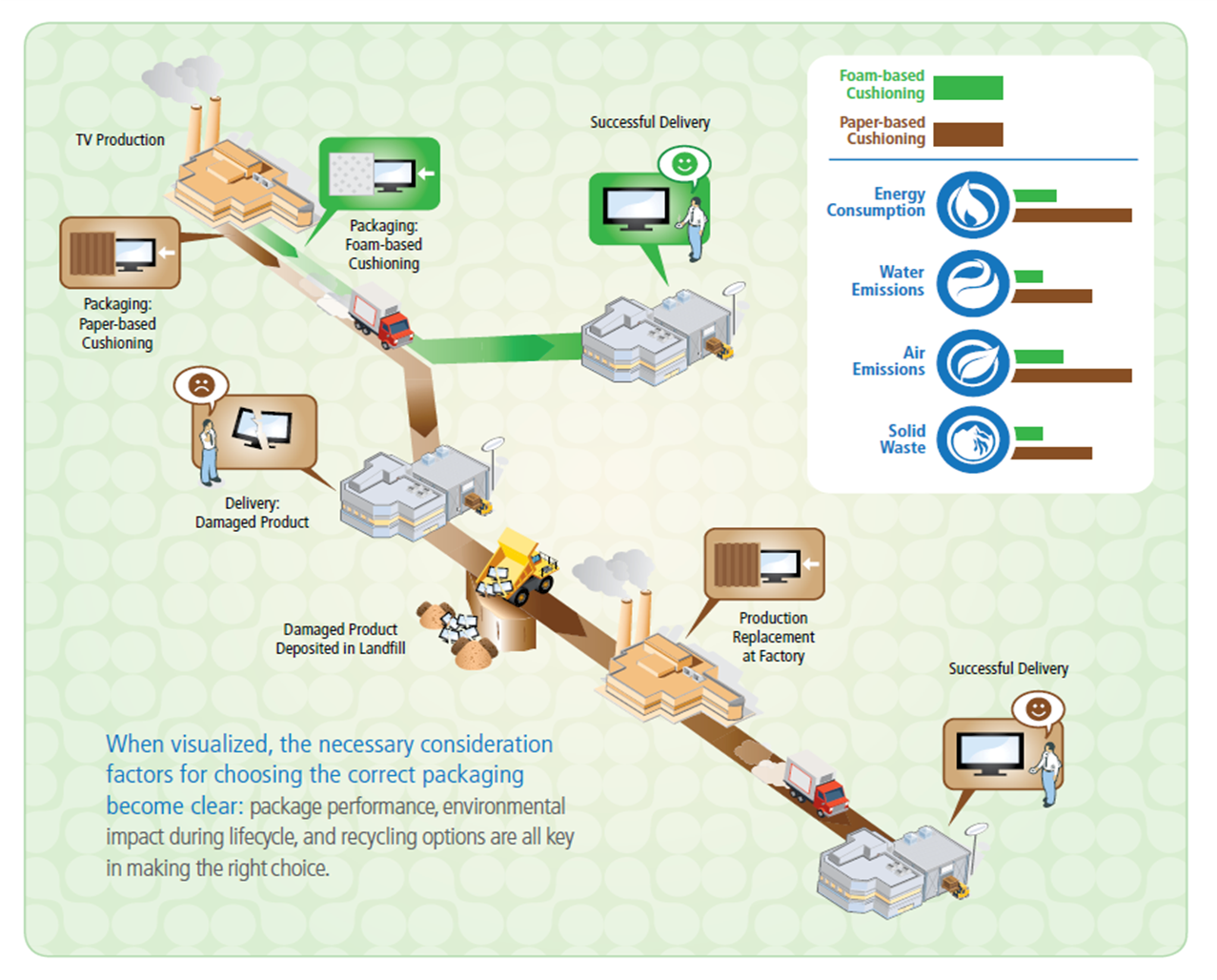

Looking For Packaging Ideas to Minimize Energy Usage?

Look no further, expanded polystyrene (EPS) is a smart, safe, and sustainable alternative to reduce overall energy usage for transport and industrial packaging.

Tags: eps, expanded polystyrene, transport packaging, industrial packaging, protective packaging, foam packaging, custom molding